Children are walking around eating gelato from a tiny stand set up inside the Bridon Bekhaert warehouse, orange helium balloons tied to wrists. Timber reels, normally used in the rope-making process, have been tipped on their side as makeshift tables, ready for Newy Burger Co who are prepping for dinner. These things feel at odds with the old industrial warehouse setting, but I’m here at Bridon Bekaert’s open day in Mayfield, Newcastle to celebrate their new company wide BeCare safety initiative.

Families and friends have been invited inside the 1920’s era factory to see how Bridon Bekaert use 100 years of specialised experience to create steel wire ropes. Exported globally, their product and history fit perfectly within Newcastle, commonly known as the “Steel City.” Their story is the perfect Australian tale, having provided local jobs in the heart of the Hunter for close to a hundred years.

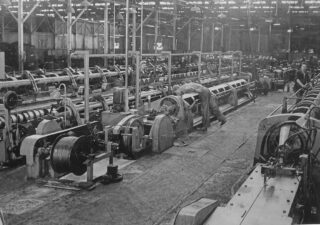

We don PPE and walk around the factory in the designated safe zones, as employees guide us past different machinery and explain the process to make steel rope. We learn about different gauges and uses of rope, specialised configurations and what a “king wire” and “acorn” is in the rope making process.

I notice some Fanquip Mancoolers along the walls, and they seem right at home in the industrial setting. The factory is built inside one giant shed, and while we are lucky enough to be here in winter, I know that the environment would get extremely hot in the summertime. All the way through the factory Mancoolers, Air Circulators and Trolley Mounted Coolers can be found, and I can’t help but spot the tell-tale splashes of Fanquip teal amongst the machinery and reels.

We go past machines in the middle of weaving small wire strands together to create product for incline haulage, shaft sinking, guides and friction or drum winders in mining. The process looks very similar to wool making but at a giant scale.

Bridon Bekaert Newcastle

Other Bridon Bekaert factories produce specialised wire, from the muselet (the wire cage that fits over the cork on champagne) to wire found in Bridgestone tyres. However, the Newcastle factory specialises in wire for industrial uses like ropes for mining draglines, highway barriers or cranes.

If you’re ever in NSW and see a truck hauling a massive red reel of steel rope, chances are that it’s from Bridon Bekaert. These giant reels when loaded with rope can weigh up to 150 tonnes.

While the art of intertwining wire, rope and cable has remained relatively unchanged since the 1920’s, it’s clear that the improvements to safety, machinery and technology are bounds ahead. The obvious items are the guards, cages and covers adorning all the of equipment, while the less obvious are the safety procedures and ongoing training. We walk past a wall of traced handprints, where each employee had to write why their hands are important, an effort to raise awareness of the effects of hand injuries.

The mix of traditional and modern make it easy to see why this warehouse has remained the provider of a vital Australian export.

Bridon Bekaert supply wire rope for the oil and gas industries, construction, underground and surface mining, the same places that our sister company, MINETEK supply innovative water, ventilation, and noise management solutions in a “two degrees of separation” tapestry to which Novocastrians are accustomed.

Bridon Bekaert have been a Fanquip customer for close to a decade, and there’s something so very Newcastle in the interplay between local companies in the region. Noticing the various locally engineered Fanquip products around the warehouse in amongst the reels, bobbins and forklifts, there’s a synergy between our two local companies and the engineering and manufacturing feats of our local region.

There’s a sense of pride to supply cooling and ventilation products to a company that in turn helps keep local jobs here in Newcastle, and many other local businesses on the move.

About Fanquip

Fanquip is an Australian made and family-owned company established in the 1980’s. We’ve delivered industrial solutions to local companies for over 30 years. We offer reliable products, custom solutions, an impressive range of solutions and friendly support from our local team.

Fanquip supplies a range of extraction, cooling filtration and heating solutions to commercial and industrial companies across Australia. The Mancoolers pictured throughout this article can be found on our website or speak to our sales team for more information about custom ventilation packages.