Australia’s food safety standards are among the highest in the world. This should come as no surprise given that Australia exports around 72% of its produce [1]. To remain competitive internationally, Australian producers need to adhere to high-quality standards for their food products.

Australia’s food regulation system is one of the most comprehensive in the world, covering everything from product labelling and nutrient content claims through processing requirements and recalls due to contamination or health concerns. With stringent regulations in place along with a comprehensive food regulation system overseen by both government agencies and industry bodies alike, Australians can rest assured knowing that their food supply is among some of the safest.

From farming practices to harvesting and packaging processes, every step needs to meet strict guidelines in order for the product to be deemed export-ready. This ensures that consumers have not only access to safe and healthy products but also high-quality ones as well.

Impacts of poor air quality

Air quality is paramount to maintaining safe and healthy food standards. Poor air quality can lead to increased airborne microorganisms, which can contaminate food and create a health crisis [2]. It can also lead to increased levels of volatile organic compounds (VOCs), chemicals released into the air from certain materials like paints or cleaning products. When inhaled over long periods, health problems can emerge. Poor air quality can reduce the shelf life of certain foods, such as fruits and vegetables, leading to spoilage and waste.

Humidity is one of the main factors that food industry workers must consider when managing their workspace. High humidity levels can cause condensation on surfaces that come into contact with cold air from refrigeration or freezing equipment. This can create an ideal environment for bacteria growth and other microbial contaminants.

Another factor that needs to be monitored is water vapour in the air. Water vapour can lead to high levels of moisture on surfaces which increases the risk of surface contamination. To prevent this, it is important to ensure that the right ventilation system is used to circulate air properly and reduce any excess moisture in the atmosphere. Good airflow will help keep ambient temperatures stable so that your food products are not exposed to extreme temperature changes, which can lead to spoilage or contamination.

Optimal ventilation for food processing

If we consider that outside air carries between 200 – 1500 bacteria per m3, a regular food processing plant could easily be supplied with millions of bacteria an hour if fitted without proper air filtration. Air extraction and ventilation must be carefully planned and implemented to ensure efficient containment of critical working areas from outside airborne pollutants (otherwise known as bioaerosols). This is why, as instructed by the Australia and New Zealand Food Standards Code, food premises must have sufficient natural or mechanical ventilation to effectively remove bioaerosols from the premises [3].

Most food quality standards give little guidance on ventilation and air filtration. Yet, food-processing facilities need about 20 to 25 ACHs per hour to remove odours, steam and other airborne contaminants and filter them out in the recycling process [4]. Although the actual number of air turns depends on the type of processing taking place in the plant and must be designed by a competent engineer to fit the facility and the process. All fans should be designed specifically for use within food production areas and should offer low-noise operation while providing adequate fresh air into the space.

Food processing temperatures

In addition to proper ventilation and airflow control systems, temperature control also plays an important role when it comes to keeping air quality at its best within a food processing facility. Ensuring temperature control throughout the food production and preparation process is an essential part of good business practice.

Temperate must be monitored and kept within a safe-zone to protect both the quality and safety of the food you offer customers. Potentially hazardous food needs to be kept at these temperatures to prevent food-poisoning bacteria, which may be present in the food, from multiplying to dangerous levels. These bacteria can grow at temperatures between 5°C and 60°C, known as the “temperature danger zone”. By maintaining temperature control, businesses can safeguard their products from hazards like food poisoning while keeping their customers happy and safe.

Air Curtains

Air curtains are a necessary part of any modern operation, helping to protect facilities and keep product quality consistent. Fanquip’s industrial Air Curtain units provide customers with a stainless-steel barrier of high-velocity air that can block out dust and insects from entering the premises. This advanced technology gives businesses peace of mind knowing they have the best protection against outside contaminants while providing superior ventilation benefits.

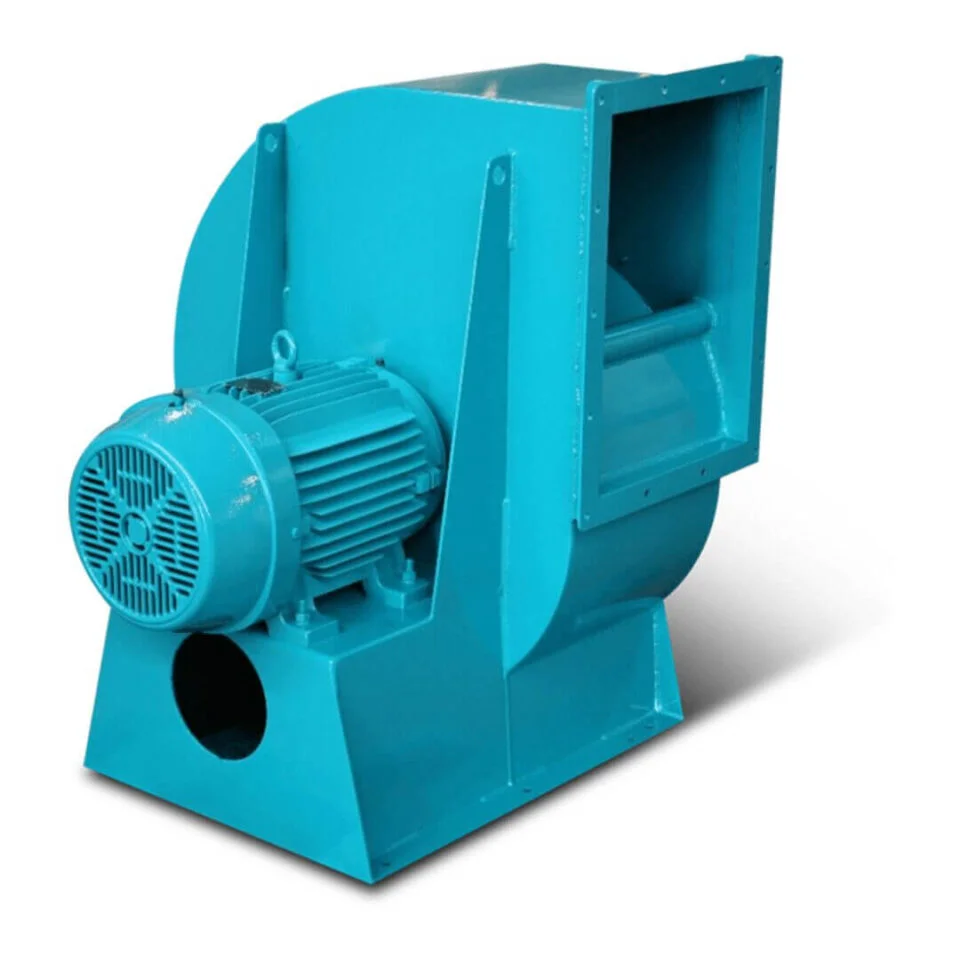

Centrifugal Fans

Centrifugal Fans operate by forcing air into a chamber and then pushing it out in a circular motion, making them ideal for ventilation. They can also be used for filter flushing, gas boosting, and aeration, as well as as a part of cooling and drying systems as well. Fanquip provides choices from direct or belt drive motor configurations, as well as specialised sizes for custom applications.

Axial Flow Fans

Axial Fans are ideal for applications that require directional air movement over a long distance, making them the perfect choice for ventilation in food processing factories. Fanquip’s Axial Flow Fans are designed and manufactured with longevity in mind; durable materials combined with a ruggedised exterior make these fans well-suited for any industry. The Axial Fan range offers two main types: Direct Drive and Belt Drive Fan Systems, providing robust, energy-efficient solutions for business owners looking to improve air circulation in their environment.

Air Circulation Fans

An effective Air Circulator provides adequate ventilation and improved air quality, leading to greater comfort and safety for personnel as they carry out their daily operations. Our vast range of Air Circulators includes pedestal, ceiling mount and wall mount fan units, which make them suitable for food processing operations. Fan features include hose-proof, stainless steel, and hazardous-rated variations to suit all environments.

Purging Fans

Fanquip is one of the leading providers of purging fans for a variety of uses. Contaminated air can often be challenging to manage, which is why Fanquip’s purging fan range is indispensable. Not only are their portable purging fans lightweight and made in Australia, but they also come with features like inlet and outlet finger guards as well as quick-release clamps. Purging Fans are perfectly suited to food processing scenarios where safety and compliance are paramount.

Fanquip is the expert in ventilation solutions with a solid understanding of how important it is to have a high level of air quality in the food processing industry. Ventilation can play a vital role in maintaining an environment free of unpleasant odours that arise during food processing, as well as regulating temperatures through heat and steam removal. We are here to help you assess and maintain your air quality, providing practical solutions to many issues, such as changes in air pressure when transferring goods or preventing condensation build-up. This brings peace of mind to food producers that their food will be safe from airborne bacteria or microorganisms.

Resources

- Australian Government – Department of Agriculture, Fisheries and Forestry – https://www.agriculture.gov.au/abares/products/insights/snapshot-of-australian-agriculture-2022

- NSW Australian Government – https://www.environment.nsw.gov.au/resources/air/mod3p3food07268.pdf

- Australian & New Zealand Food Standards Code – https://www.legislation.gov.au/Details/F2021C00674

- Food Safety Magazine – https://www.food-safety.com/articles/3832-in-plant-air-handling-and-food-safety-there-is-a-connection