In the rigorous and demanding field of steel production, maintaining optimal working conditions is not only crucial for productivity but also for ensuring the safety and well-being of workers. As steelworks operations generate extreme heat and potentially harmful fumes, effective ventilation solutions are indispensable. This blog explores the common ventilation challenges faced by steel facilities, the innovative solutions offered by Fanquip, and real-world applications that demonstrate the effectiveness of these solutions.

What are the Ventilation Challenges in Steel Facilities?

Steel facilities face several significant ventilation challenges that are critical to address for the safety, efficiency, and regulatory compliance of operations. Here are the main challenges:

Heat Control

Steel production generates substantial heat, with processes like melting, forging, and rolling operating at extremely high temperatures. Managing this heat is crucial to maintain a safe working environment and to protect equipment from overheating, which can lead to mechanical failures or reduced efficiency.

Airborne Contaminants

Steel production processes, such as welding, cutting, and smelting, release various airborne contaminants, including dust, fumes, and gases. These contaminants can be hazardous to health, causing respiratory problems and other health issues among workers. Effective extraction and filtration systems are needed to capture these contaminants at the source and prevent them from spreading in the work area.

Humidity Control

High levels of humidity can occur in steel facilities due to processes involving high temperatures and the presence of open water sources used for cooling. Excess humidity can lead to corrosion of equipment and infrastructure and can affect the quality of the steel products. Proper ventilation is necessary to manage humidity levels and minimise these risks.

Welding Fume Regulation Compliance

Recent changes in regulations in Australia, particularly concerning welding fumes, have tightened the permissible exposure limits. Facilities must now have more robust systems to capture and filter welding fumes to protect workers’ health and comply with occupational safety standards.

Read more in our blog: New Workplace Exposure Standard For Welding Fumes Announced

Energy Efficiency

The large-scale ventilation required to effectively manage air quality and temperature in steel facilities can lead to high energy consumption. Implementing energy-efficient ventilation solutions can significantly reduce operational costs and contribute to more sustainable production practices.

Confined Spaces

Steel facilities often contain confined spaces where the buildup of hazardous gases can occur. Specialised ventilation solutions are required to ensure adequate air exchange and to prevent the accumulation of explosive or toxic gases in these areas.

Addressing these challenges requires a combination of advanced ventilation technology, rigorous safety protocols, and ongoing maintenance to ensure that systems are functioning properly and adapting to the evolving needs of the facility. Effective ventilation not only creates a safer and more comfortable working environment but also enhances productivity and ensures compliance with health and safety regulations.

Fanquip Ventilation Solutions for Steelworks

At Fanquip, we understand the critical role ventilation plays in maintaining optimal conditions within steel facilities. Our range of industrial ventilation solutions is designed to address the diverse and demanding needs of steel production processes, from controlling intense heat to capturing harmful airborne contaminants. Here’s how our specific products cater to these needs:

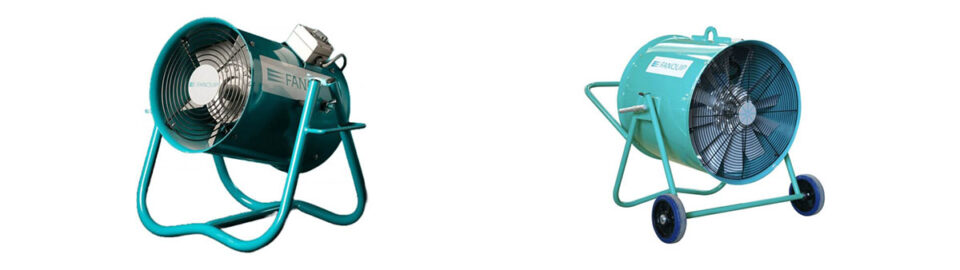

Mancooler Fans

Our Mobile Mancooler Fan is specifically engineered to target equipment and staff cooling needs in dynamic and high-temperature environments. These portable fans offer flexible cooling solutions, making them ideal for quickly addressing heat hotspots within a steel facility. They are perfect for providing direct, powerful airflow where it is most needed, significantly improving comfort and operational safety for workers.

Mobile Fume Extractors

The Mobile Fume Extractor from Fanquip is designed for effective at-source collection of hazardous fumes and particulate matter. Commonly utilised for capturing welding fumes, grinding dust, and other dry particulates, this extractor features a robust two-stage filtration system, incorporating both a pre-filter and a HEPA filter to ensure thorough air purification. Its durable, powder-coated finish and solid construction allow it to perform reliably even in the toughest industrial conditions.

Centrifugal Fans

Our Backward Inclined Centrifugal Fan delivers exceptional performance in demanding environments, making them a key component of any industrial ventilation system. These fans are designed to efficiently move large volumes of air, capable of handling both high temperatures and various airborne contaminants. Their robust design ensures they can effectively dissipate heat and remove pollutants, thus maintaining a safe and compliant working environment within steel production facilities.

Each of these products plays a crucial role in maintaining strict hygiene, controlling temperature and humidity, and ensuring product quality and worker safety in steelworks. Whether it’s reducing heat stress in the workplace, controlling dust and fume levels, or providing general air movement, Fanquip’s solutions are designed to meet the rigorous demands of the steel industry.

Fanquip Case Studies in Steel

A notable application of our ventilation solutions is at Bridon Bekaert in Newcastle. This steel wire rope manufacturer faced challenges managing the heat generated in their processes, particularly during summer. By integrating Fanquip’s Mancoolers and air circulators, they achieved significant improvements in air quality and temperature control, enhancing both productivity and workplace safety. This installation not only supported their operational efficiency but also underscored Fanquip’s commitment to delivering industry-leading ventilation solutions.

Get Expert Advice for Industrial Ventilation

Fanquip is dedicated to providing the best ventilation solutions tailored to the specific needs of commercial and industrial businesses in Australia. With our expertise in managing ventilation challenges in various industrial settings, including steelworks, we ensure your operations meet all safety and quality standards while maintaining high efficiency.

If you are facing ventilation challenges in your facility, contact us today to learn how our solutions can enhance your working environment, ensure compliance with health regulations, and ultimately, improve your operational outcomes. Our team of experts is ready to provide you with the advice and support needed to implement the optimal ventilation system for your needs.

By integrating Fanquip’s solutions, you can ensure your steelworks facility is not only compliant with the latest regulations but also a safer, more productive place to work.