In the critical sectors of sewerage and drainage, the significance of robust ventilation systems cannot be overstated. These systems are not only pivotal for maintaining air quality but are also essential for ensuring the safety and efficiency of operations within these confined and often hazardous environments. This blog post delves into the unique challenges of sewerage and drainage ventilation, outlines key considerations, and showcases Fanquip’s innovative solutions that are making a difference in the field.

Common Challenges for Ventilation in the Sewerage & Drainage Industry

The sewerage and drainage industry is fraught with ventilation challenges that can significantly impact the health and safety of workers, as well as the efficiency and reliability of the sewer systems.

Hazardous Gases & Odour Control

One of the most pressing issues in sewer and drainage systems is the accumulation of hazardous gases such as methane and hydrogen sulphide, which can pose serious health risks. These gases, along with the unpleasant odours they often carry, necessitate effective ventilation solutions to ensure worker safety and community comfort.

Confined Spaces

Manholes and tunnels present unique challenges due to their confined nature. Ensuring adequate airflow in these tight spaces is crucial to prevent the build-up of toxic gases and to ensure a safe working environment for professional plumbers and maintenance crews.

System Efficiency

Inadequate ventilation can lead to a range of problems, including gurgling sounds in the plumbing systems, slow water flow, and even back-ups in the drain line. Ensuring the ventilation systems are optimally designed and functioning is crucial for the overall efficiency of the sewer network.

Key Considerations for Ventilation in the Sewerage & Drainage Industry

Designing and implementing effective ventilation systems in the sewerage and drainage industry requires careful consideration of several factors:

Proper Venting Design

The design of the vent system, including the placement and size of plumbing vents, air vents, and vent stacks, is critical. A well-designed venting system ensures there is enough air flow to allow water to flow freely through the sewer systems while preventing the backflow of sewer gases into buildings or public spaces.

Airflow Dynamics

Understanding the airflow dynamics within sewer networks and drainage systems is essential for effective ventilation. This includes considering the volume of air that needs to be moved, the speed of airflow required, and the best types of fans and ventilation equipment to achieve these objectives.

Material & Equipment Durability

Given the harsh conditions within sewerage and drainage systems, including high humidity, corrosive gases, and variable temperatures, the materials and equipment used for ventilation must be highly durable and resistant to corrosion.

Environmental & Health Regulations

Compliance with environmental and health safety standards is paramount. Ventilation systems must be designed to meet or exceed regulatory requirements to protect workers and the public from the potential hazards associated with sewer and drainage operations.

Fanquip Ventilation Solutions

Fanquip has been at the forefront of providing advanced ventilation solutions tailored to the unique needs of the sewerage and drainage industry. Our focus on innovation and quality has led to the development of products that address the specific challenges faced by our clients in this sector.

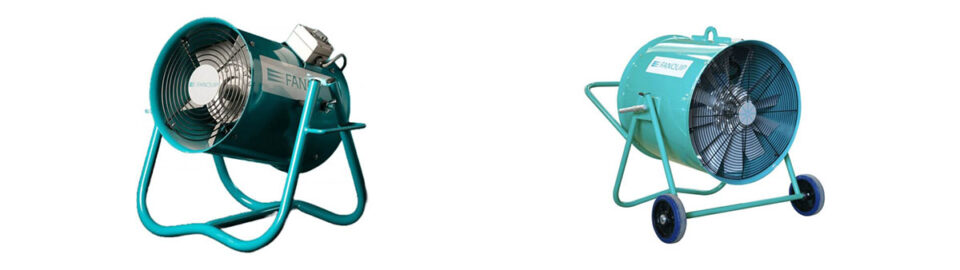

Mancoolers: Mobile and Mini Solutions for Confined Spaces

Our Mancoolers, available in both mobile and mini versions, are designed for optimal performance in confined spaces like manholes. These units provide the necessary airflow to disperse hazardous gases and reduce heat, ensuring a safer working environment for maintenance and repair teams.

Direct Drive Axial Flow Fans: High Airflow with Low Energy Consumption

The Direct Drive Axial Flow Fans are engineered to meet the high airflow requirements of sewerage and drainage applications while minimising energy consumption. Their design is particularly beneficial for tunnel ventilation, where maintaining air quality over long distances is crucial.

Fanquip Case Studies in the Sewerage & Drainage Industry

Fanquip has been instrumental in providing cutting-edge ventilation solutions tailored to the unique demands of the sewerage and drainage industry. Through our collaboration with industry leaders, we have developed and implemented systems that not only enhance operational efficiency but also ensure safety and compliance with environmental standards. Here, we explore some of the notable projects that underscore our expertise and innovative approach in this sector.

Project 1: Metrocorp Technologies Tunnel Ventilation

Metrocorp Technologies, a company with over three decades of experience in remedial construction and water infrastructure, required an advanced ventilation solution for a tunnel project. The challenge was to extract contaminated air effectively while ensuring the air released to the atmosphere was clean and safe.

Fanquip’s Solution: We supplied five extraction fans, equipped with an activated carbon filter setup at the tunnel’s end, capable of extracting a total of 12,000 litres per second. This setup ensured that the air, once filtered through the carbon system, was free from contaminants before being released. To meet the project’s specific needs, we provided a special Containerised Tunnel Fan and an Acoustic Fan Assembly, designed for high airflow requirements at low pressure. This not only assured efficient ventilation but also minimised electrical costs, addressing the client’s concern about the axial fan capability to handle the duct pressure.

Project 2: Comprehensive Tunnel Ventilation for Enhanced Air Quality

In another ambitious project, the need was to ventilate a 1.5km long tunnel effectively, especially critical during the summer months when gas levels, particularly hydrogen sulfite, tend to rise.

Fanquip’s Solution: The project demanded a robust solution that could eliminate the need for multiple mancoolers. We introduced a larger, variable speed fan capable of pushing air through the extensive tunnel length. This fan was strategically placed to blow air into a road manhole within a residential area, requiring careful consideration of noise and air quality impact on the surrounding community. To accommodate the existing infrastructure, we ensured compatibility with the existing ductwork, with provisions to upscale to an 800mm diameter if necessary.

Project 3: Interflow’s Pipeline & Manhole Ventilation

Interflow, a leader in water and pipeline infrastructure, required a versatile ventilation solution that could be adapted to various pipeline works and manhole ventilation requirements.

Fanquip’s Solution: Recognising the diverse needs of pipeline and manhole ventilation, we supplied Interflow with a range of mobile and mini Mancoolers, along with necessary ducting. The 600mm Mancoolers were particularly favoured for their compatibility with all manhole sizes, while the 1000mm units were reserved for longer duct runs and tunnel applications. This flexibility allowed Interflow to customise ventilation based on the specific requirements of each project, ensuring optimal air quality and worker safety across their operations.

Conclusion

The challenges of ventilation in the sewerage and drainage industry are complex, but with careful consideration and the right expertise, they can be effectively managed. Fanquip’s commitment to innovation and quality has made us a leader in providing ventilation solutions that enhance safety, efficiency, and reliability in this critical sector. Our tailored solutions, designed to meet the specific needs of our clients, demonstrate our dedication to addressing the unique challenges of the sewerage and drainage industry, ensuring safer and more efficient operations across Australia.