Axial Flow Fan vs Centrifugal Fan

Fans come in many different shapes and sizes, but they all have one common goal: to move air. The two most common types of industrial fans are axial fans and centrifugal fans. Other fan terminologies used in the industry are industrial blowers, industrial ventilation fans, industrial exhaust fans, blower fans and HVAC fans, all of which are used to define Centrifugal or Axial fans.

Is an Axial or Centrifugal Fan better?

Each fan type has its own unique advantages, making it suitable for different applications. Axial fans are more efficient at moving large volumes of air across long distances, making them ideal for industrial applications. Centrifugal fans, on the other hand, are more powerful and can move air at higher speeds. This makes them ideal for creating a cooling effect in rooms or other enclosed spaces. The design and function of an axial fan is very different in comparison to centrifugal fans.

So, which type of fan is better? Ultimately, it depends on the specific application. Both axial and centrifugal fans have their own strengths and weaknesses, so choosing the right one is a matter of matching the fan to the job at hand.

| Axial Fans | Centrifugal Fans |

| High volume & low pressure | High pressure & low volume |

| Expels air parallel to intake | Discharge at 90-degree angle from intake |

| High operating speed | Low operating speed |

| Compact design | Ideal for specific directed cooling |

| Low power consumption | Consumes more power than Axial Fans |

| Low noise | Higher audible noise than Axial Fans |

| Typically cheaper than centrifugal fans | Durable & designed for demanding applications |

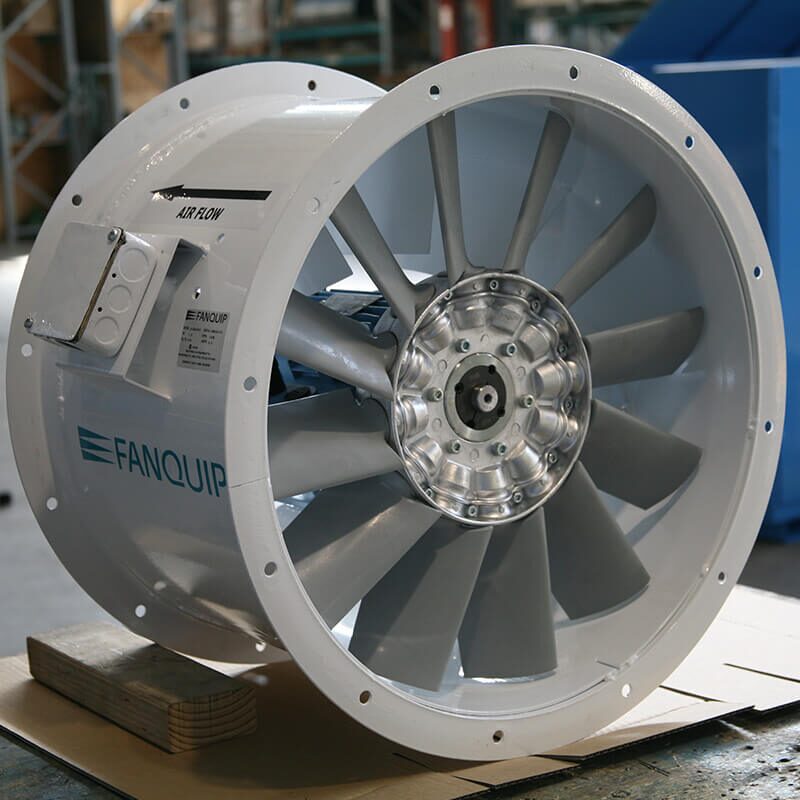

Axial Fans

Axial fans are well-suited for applications that require a large volume of air to be moved over a long distance. This type of fan uses blades to push air directly ahead, making it very efficient at moving air in a straight line. This makes axial fans ideal for use in industrial settings, where they are often used to ventilate large spaces such as factories, warehouses or underground mining operations.

Fanquip axial flow fans are ruggedised units made in Australia to withstand harsh operating conditions across all industries. The two main products in the line are the direct drive axial flow fan and the belt drive axial flow fan.

Belt Drive Axial Flow Fan

Belt drive axial flow fans move large quantities of air at low pressures, making them ideal for a range of settings. The motor is installed independently of the fan blades and connected to them through belts and a pulley system. Belt driven axial flow fans offer greater flexibility in regard to RPM speed, however they are typically more expensive than direct-drive axial flow fans of comparable size.

As the motor is externally located and kept away from the airstream, belt-driven axial fans are safer to use in settings where the air temperature or fumes present pose a safety hazard. Fanquip’s belt drive axial flow fans are proudly Australian-made, with a hot-dipped galvanised casing, an aerodynamic belt tube, and a heavy industrial rolled casing.

Direct Drive Axial Flow Fan

Direct drive axial fans offer a number of advantages over belt-driven axial fans. One of the most significant advantages is that direct drive fans are much more energy efficient, due to reduced friction. Typically, direct drive axial fans require less maintenance than belt-driven fans, as belts may need to be replaced or repaired. This fan type can handle hazardous fumes, removing and dispensing contaminated air from industrial processes which generate heat, steam, dust or other noxious emissions. Please ensure that you choose specific optional extras such as IP66 motors and hazardous locations when ordering your axial flow fan.

Centrifugal Fans

Centrifugal fans are more powerful than axial fans and can move air at higher speeds. Centrifugal fans are a type of fan that uses centrifugal force to draw air into the blades and then move it out at a 90-degree angle, creating a rotating column of air. These fans are very efficient at conveying gas or other materials, which is why they are often used in air conveyor systems or other materials handling processes. Centrifugal fans can also be used for filter flushing, gas boosting, and aeration. With a diverse range of applications, Centrifugal fans can be used as a part of cooling and drying systems as well.

At Fanquip, we offer a wide range of heavy industrial materials handling, high pressure and custom centrifugal fans to suit all applications. Choose from a range of sizes, direct or belt drive motor, and more. We offer special configurations to suit your specific needs, all of which are proudly Australian-made. If you are looking for an efficient and reliable way to move gas or other materials, a centrifugal fan is a great option.

Axial vs Centrifugal Fans

The main difference between axial and centrifugal fans is the way they move air. Axial fans blow air in a linear fashion, while centrifugal fans use a rotating impeller to draw air into the blades and then push it out at a 90-degree angle. Centrifugal fans are more powerful than axial fans and can move air at higher speeds.

Applications

Axial fans are typically used in industrial settings, where they are often used to ventilate large spaces such as factories, warehouses or underground mining operations. Centrifugal fans can be used for a variety of applications, including cooling and drying systems, filter flushing, gas boosting, and aeration.

Benefits

Axial fans are usually more energy efficient than centrifugal fans, as they have reduced friction. Centrifugal fans can be more compact than axial fans, making them easier to install in tight spaces.

There is no clear answer as to whether axial or centrifugal fans are better, it depends on the application and what benefits are most important. In general, axial fans are more energy efficient and require less maintenance, while centrifugal fans are more powerful and can move air at higher speeds. Contact Fanquip to discuss your fan requirements and applications, or shop online today. From consultation to customised solutions, and installation, Fanquip is here with you all the way through.