Food processing ventilation is a cruical aspect of any meat handling or food facility. According to industry research from Food Standards Australia and New Zealand, there were 75 food recalls in 2022. Ventilation is essential in order to reduce the potential for contamination in a food processing plant. Is your food processing facility doing enough to reduce the food recall risks?

This article will explore the consequences of inadequate ventilation in the food processing industry, along with the ventilation design considerations you must know.

The importance of food processing ventilation.

Here are some of the top reasons why ventilation is crucial in the food processing industry:

- Controlling odours, fumes, and airborne contaminants to protect workers’ health.

- Maintaining indoor air quality and controlling airborne microorganisms and allergens, reducing the risk of contamination and recalls.

- Providing exhaust for humidity and moisture can compromise worker health and product quality by encouraging mould growth.

For these reasons, it is dictated by Food Standards Health and Safety Authority that you should have sufficient natural or mechanical ventilation to meet air quality standards for food processing.

What are the critical considerations for ventilation in food processing plants?

Let’s discuss the core considerations you should make for industrial ventilation design at a food processing plant.

Air Distribution

Air distribution plays a vital role in the ventilation of food processing plants. It ensures an industry-compliant air exchange rate, reducing stagnant air pockets. Air pockets can become hosts to contaminants and condensation, preventing contamination.

Air distribution is also key in maintaining even temperature distribution throughout the facility for more comfortable working conditions.

Filtration

Filtration should be a top priority for reducing contamination in a food processing plant. Solutions like Air Curtains helps to capture any dust, debris, contaminants, and allergens present in the air, preventing them from causing product recalls – which can be highly costly for food processing companies.

Pressurisation

Here are some of the reasons why pressurisation is so crucial for food processing ventilation:

- Hygiene – Pressurisation helps to maintain higher air pressure which prevents contaminants from ingressing into clean rooms and packaging areas.

- Containment – When working with raw materials or performing waste management, high air pressure can help you to contain the materials and odours for more safe and compliant practices.

Temperature/humidity

Temperature and humidity should be maintained with food processing ventilation systems. The facility’s temperature should be even, without warm or cold air pockets. This will ensure that temperature variations do not encourage mould or bacteria growth and that cold spaces preserve food products. Humidity, too, should be regulated to ensure the facility remains mould-free

Top ventilation solutions for the food processing industry

Now that we have explored why ventilation is necessary in the food processing industry, let’s discuss the leading food processing industry fans.

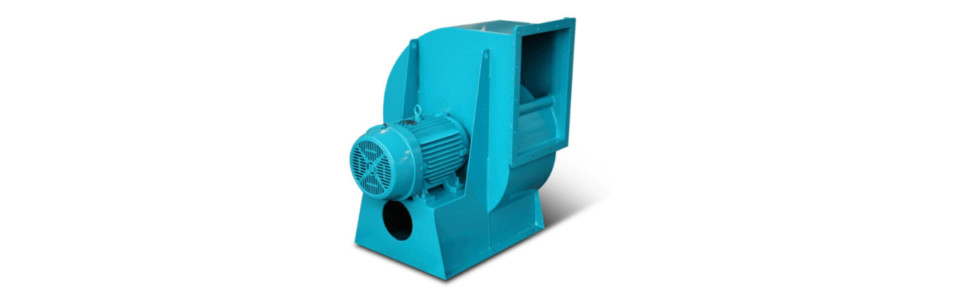

Backward-inclined centrifugal fans

Backward-Inclined Centrifugal Fans are ideal for food processing industries. The fan has a backward tilt to prevent contaminants from accruing on the surface of the fan blades. You can expect quiet operation and high efficiency from this fan type.

Vertical discharge roof fan

A Vertical Discharge Fan provides airflow exchange and temperature distribution within a food processing plant. It provides an upward airflow to exhaust contaminated air and replenishes the facility with fresh, clean air.

Air curtains

Air Curtains are an energy-efficient solution for preventing cross-contamination within a food processing plant. They provide a thermal barrier to prevent hot or cold air from escaping an area. Fanquip’s Air Curtains also ensure that no air filtration occurs, leading to cross-contamination between food processing areas.

Wall-mount air circulators

Wall-Mount Air Circulators have a discreet design and are ideal for smaller food processing facilities. They provide increased airflow circulation while offering versatile placement potential.

Portable purging fans

Portable Purging Fans are ideal if you are seeking a maneuverable solution for your food processing plant. A portable purging fan provides extraction and filtration for the air, ensuring no contamination. Moving it to different areas within your facility is easy as needed.

Choose Fanquip for food processing ventilation solutions

Food processing facilities require ventilation solutions to prevent cross contaminations and allergens, which can lead to litigation and product recalls. Ventilation also reduces humidity and regulates temperature to ensure worker comfort.

There is a wide variety of ventilation solutions to choose from – offering filtration, temperature distribution, and air circulation required in food processing facilities. If you need assistance in choosing the right solutions for your facility’s specifications, you should contact our team at Fanquip today.