A poorly ventilated meat processing plant can lead to a number of concerns, including the spread of viruses, diseases and food contaminants. Air quality is considered a leading contributing factor to cross-contamination, and microorganisms are often responsible for outbreaks of food spoilage, as well as food-related illnesses.

With the increased demand for safety in the meat processing industry, performing hazard assessments and implementing proactive safety measures is essential.

Keep reading as we explore why ventilation is important in health and safety at meat processing facilities and the recommended ventilation solutions.

What is the purpose of ventilation in the meat processing industry?

Understanding why ventilation is instrumental to meat processing health and safety will help you measure your ventilation system’s effectiveness. Here are some of the crucial functions ventilation plays in your meat processing health and safety strategy:

- Removing airborne contaminants – when processing meat, you must consider the potential for contamination. Blood mist, meat particles, and gases can all become airborne during meat processing. To reduce the potential for harmful bacteria growth and contamination, you must provide ventilation for clean and breathable air.

- Temperature and humidity control – you must maintain a specific temperature and humidity level to prevent the meat from spoiling and to prevent bacteria growth. Ventilation helps to provide even temperature distribution while lowering humidity levels.

- Odour mitigation – processing raw meat can emit potent odours, harming employee wellbeing. Ventilation solutions often provide carbon filters and scrubbers to reduce odours and provide a more comfortable and pleasant working environment.

For the above-listed reasons, it is essential to focus on providing proper ventilation in the meat processing industry.

Top ventilation solutions for the meat processing industry

Now that you understand the ramifications of poor ventilation in the meat processing industry, let’s discuss the best ventilation methods and solutions. Below is a list of meat processing facilities’ top fans and ventilation systems.

Mancoolers

A Mancooler is tailored to provide targeted airflow to specific areas within a meat processing plant. A Mancooler can provide air circulation for cutting tables and packaging stations. They provide high-velocity airflow ranging from 472 to 4720 l/s.

They can help to reduce heat and odours produced by manufacturing processes. Their compact size makes them extremely versatile and maneuverable, allowing you to direct airflow where needed.

Roof Fans

Roof Fans are fitted to the roof of your facility to provide exhaust. They can help to remove humidity, hot air, fumes, and contaminants from the air. This is a large fan better suited to a large-scale facility. They have a high airflow capacity with vertical discharge. They help to reduce stagnant air pockets for even temperature distribution, reducing condensation and moisture buildup.

Exhaust Fans

An Exhaust Fan can be mounted on the walls or ceiling of your facility, depending on your layout and requirements. They come in a wide range of sizes and provide extraction for stale air, contaminants, and moisture in meat processing facilities.

The Exhaust Fan will create a strategic airflow pattern to provide even temperature distribution and extraction for processing areas. Larger units can provide over 47,000 l/s.

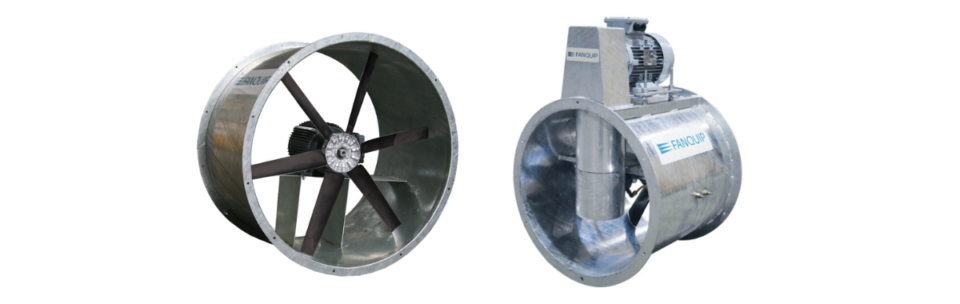

Axial Fans

An Axial Fan creates airflow parallel to the fan’s axis and can be mounted on a wall, incorporated into your duct system, or used as a portable solution. They are recommended for air circulation to cool meat processing equipment while exhausting odours and contaminants. The capacity of an Axial Flow Fan will depend on its size, ranging from as little as 47 to 47,000 l/s.

Air Curtains

Air Curtains, or air doors, are often installed above doors or openings in meat processing facilities. They provide a high-velocity air barrier to prevent the entry of insects, dust, and outdoor contaminants. They also offer temperature control, ensuring temperate air does not escape the facility and hot air does not enter. The right Air Curtain size depends entirely on the size of your door frame.

Centrifugal Fans

A Centrifugal Fan provides a high volume of airflow for manufacturing facilities. It has a high-speed rotating impeller encased in a spiral-shaped casing to accelerate the air and discharge it in a radial direction. Depending on your specifications, you can choose a backward, forward, or radial blade design. These fans are typically employed to provide exhaust and air circulation for meat processing facilities.

Choose Fanquip for meat processing ventilation solutions

All eyes are on the meat processing facility right now, demanding more diligence for health and safety. Ventilation should be top of mind when planning your meat processing health and safety strategy.

If you’re unsure about your airflow exchange requirements, or the best ventilation solution for your facility, you can rely on the Fanquip team for expert advice. Contact us today for assistance in complying with industry regulations and providing your employees with a safe and comfortable work environment.