Textile and clothing manufacturing is a small yet important industry and contributes to 1.5% of the Australian GDP. Australian made textiles are in high demand with the fall of fast fashion and the rise of high quality, ethically made, local clothing and fibre products. However, the manufacturing of textiles or clothing wouldn’t be able to occur safely or efficiently without a proper ventilation system.

Keep reading as we explore why ventilation is essential for the textiles industry along with the the top ventilation solutions to keep your operations running smoothly.

Why is ventilation essential for the textile industry?

Different Australian fibre products and materials are used in the textile industry to create clothing and valuable materials for manufacturing processes. Here are some of the complex fabric manufacturing processes involved in textile operations:

- Production of fibres

- Arrangement of fibres into yarns

- Generating fabric from raw materials

- Processing fabrics to perfect the finished product

For each process, manufacturers must maintain optimal humidity and temperature levels to ensure the quality and workability isn’t compromised.

Textile facilities require industrial graded ventilation solutions to maintain ambient conditions. The reliability and performance of these ventilation solutions are paramount as failure could lead to losses, ruined materials and increased industry waste.

How does ventilation benefit textile operations?

What will you gain by ensuring proper ventilation for your textile industry operations? Let’s take a look;

Worker health

Ventilation helps to manage airborne contaminants like bacteria or viruses, ensuring air quality breathable air. As a result, your workers will have better health and a lowered risk of respiratory conditions. Inhaling lint, dust, and other particles can lead to aggravated asthma and other serious conditions, which is why filtration and ventilation are so important.

Managing air pollution

In an industrial environment, there are pollutants produced by other manufacturing plants that seep into the air. An air conditioning unit cannot manage these pollutants and prevent them from affecting air quality. The fabrics could become soiled in this atmosphere by electrostatic attraction or dust accumulation. A filtration ventilation device helps manage air pollution and remove airborne dust and contaminants to stabilise working conditions.

Decreased waste

Industrial ventilation solutions maintain air quality while regulating temperature and humidity levels. Creating consistent air quality conditions can improve the quality assurance of your textile products. There will be no dust, contaminants, mould growth or temperature and humidity fluctuations to impact your products, and hence, you won’t need to waste valuable materials due to spoilage and will in turn save money.

Seasonal

You can keep your workers cool during the summer by providing air circulation and even temperature distribution with ventilation. This will prevent heat stress, dehydration, and other obstacles to productivity and worker safety. Ventilation is also important during winter due to increased condensation, creating an ideal environment for mould and mildew growth. An effective ventilation solution caters to both the winter and summer months and improves indoor air quality.

Top ventilation solutions for the textile industry.

Now you know the benefits of ventilation for textile operations, it’s time to equip your facility with the most effective ventilation solution for your application. But which ones should you choose? Here are the top recommendations for textile industry ventilation:

Direct-Drive Axial Fan

Direct-Drive Axial Fans efficiently move large volumes of air, maintaining consistent humidity and temperature levels. This type of axial fan is more energy efficient than the belt drive axial fan system as the Direct Drive Axial Fan does not require ductwork or belt operation.

Belt-Drive Axial Fan

Belt-Drive Axial Fans may not be as energy-efficient as direct-drive alternatives. However, they provide more flexibility for fan speed, enabling precise control. You can adjust the fan speed based on your facility’s size, the seasons, and other factors.

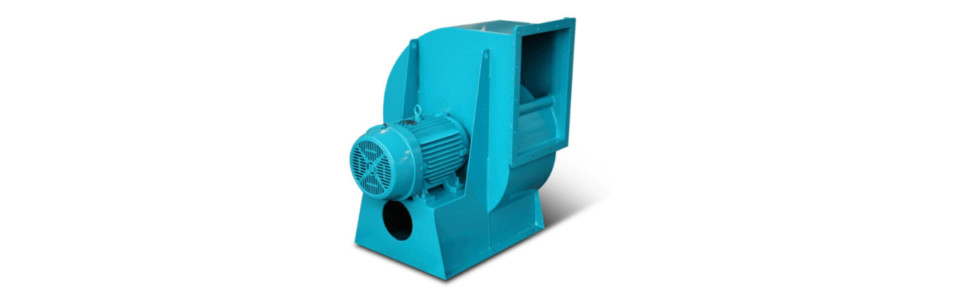

Centrifugal Fan

A Centrifugal Fan is a valuable ventilation solution for the textile industry as it can manage high static pressure requirements. It maintains airflow under various system resistances, making it ideal for dust extraction and air filtration. A centrifugal fan prevents your textiles from becoming soiled while reducing the likelihood of occupational lung hazards.

Choose Fanquip for textile industry ventilation planning

In the textile industry, leaders must consider ventilation as an integral component of product integrity and quality assurance. Any temperature, humidity, and dust level fluctuations can result in product spoilage, waste, and losses.

If you’re planning the ventilation solution for your textile facility, our team of ventilation technicians and engineers can assist. We offer expert advice to help you comply with your industry sector’s ventilation regulations – Contact us to learn more.