Running your own business is rarely easy, especially in the commercial laundry industry. Commercial laundry businesses often manage many orders daily, and managers or owners can juggle a lot of work.

For this very reason, having support whenever possible is likely beneficial, especially when it requires certain technical expertise. If you’re wondering what the commercial laundry ventilation requirements and regulations are, we’re here to help.

What are the commercial laundry ventilation requirements and regulations?

Ventilation requirements and regulations differ among industries. When it comes to commercial laundry services, the National Construction Code (NCC) by the Building Code of Australia (BCA) put in place AS 1668.2-2012. This requires a minimum extraction capacity of 40 litres per second for commercial laundries where a non-condensing dryer is installed.

If a condensing dryer is installed, this requirement drops to 20 litres per second. Either way, commercial laundry companies must have certain pieces of equipment to meet these standards.

Why do commercial laundries need ventilation?

Domestic laundry machines can generate quite a lot of steam on their own. Therefore, commercial laundry businesses that use a number of high-powered machines can certainly make even the largest buildings humid in a short amount of time. This is why ventilation is essential.

There are several benefits to ventilation in a commercial laundry business, such as:

- Combating moisture and condensation

- Reducing fire hazards

- Improving air quality

We explore these benefits in more detail, explaining why businesses should take them seriously.

Moisture, condensation & humidity.

Moisture buildup can be a significant problem in commercial laundry buildings. Excessive humidity can lead to mould and mildew growth, which can be hazardous to the health of your employees.

These issues are inevitable without proper ventilation, but installing just one or two mechanical ventilation devices can make a huge difference; this is why certain legislation exists. For example, Side Wall Exhaust Fans can extract large volumes of heat, steam or dust from a commercial laundry setting successfully.

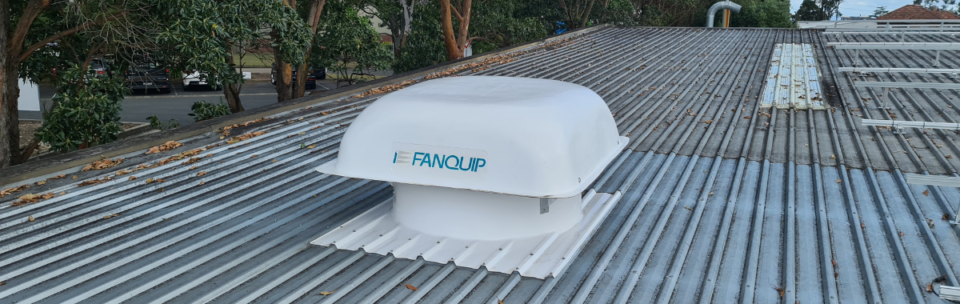

A Curb Base Hooded Roof Fan extracts moisture from the air and therefore reduces humidity in a building. This means that your laundry machines are less likely to damage the rooms they’re in and affect how those that work their breath.

Fire hazards.

Poor ventilation in a particular room can increase the overall temperature and, therefore, increase the risk of fire. Wall Mount Air Circulators are used in commercial laundries for cooling and fire hazard reduction. Air movement prevents the build-up of lint forming on machinery and the building structure which poses a potential fire hazard risk.

To reduce the likelihood of spontaneous fire, it is important to maintain proper ventilation by keeping tumble dryer air exhaust vents clear of blockages. Additionally, avoid storing dirty laundry near heat sources such tumble dryers or in areas with direct sunlight.

Air quality.

While you may not think about it day-to-day, the air quality of a commercial laundry building is essential. It can impact short-term things like you’re mood, as well as affect long-term issues such as your overall lung health.

The products often found in commercial laundry buildings contain air pollutants and can build up to a harmful level over time.

Poor ventilation can lead to a build-up of carbon dioxide and reduce overall oxygen in a building, this can cause shortness of breath, headaches and fatigue.

Why is commercial laundromat equipment so important?

With all this in mind, it’s clear that extracting stale and potentially harmful air is vital.

Commercial laundry equipment is an essential part of any commercial laundry business, and with various options available, the necessary technology should be implemented.

Opting for a product like a Profile Base Hooded Roof Fan can successfully extract and replace it with fresh air from your commercial laundry setting.

Whether you just need a few Roof Fans or require a multitude of ventilation methods, Fanquip is here to support you and make sure you’re meeting the necessary requirements.

Fanquip can support you in all your ventilation needs.

If you’re looking to set up a ventilation system for your commercial laundry service, Fanquip is here to support you. They can help explain the difference between something like a Vertical Discharge Roof Fan and an End Wall Exhaust Fan, so you know exactly what you need.

Our team of professional ventilation engineers can help you customise and design a system that complies with all the necessary building codes and safety standards.

Take a look at our services today, and contact a member of the team to get started.