In most cases, strong odours don’t have any long-term consequences for your health. But, they can become unpleasant and nauseating for employees in the food preparation industry.

What causes unpleasant odours in a food preparation facility, and how can you manage these smells?

Keep reading as we explore the top strategies for managing food odours in manufacturing – creating a more pleasant and sustainable working environment for your employees.

What causes unpleasant odours in the food preparation industry?

Let’s take a look at the main culprits for unpleasant odours in food preparation.

Food processing

Food preparation processes emit smells and odours. Cooking, frying, and other food preparation processes contribute to the dissipation of food smells by emitting volatile organic compounds (VOCs) into the air.

These VOCs can cause distasteful smells – particularly compounds like sulphur and aldehydes. Burnt and toasted odours can also affect employees and quickly lower working conditions.

Garbage rooms

When operating a food processing facility, you must dispose of excess food and parts unsuitable for consumption. This waste is stored in a garbage room until it can be disposed of and removed from the facility. Organic waste can cause the emission of foul-smelling gases. This is because the organic matter decomposes, producing malodourous compounds such as ammonia, hydrogen sulphide, and volatile fatty acids. This smell is similar to the odours emitted by your household bin – only on a much larger scale due to the industrial environment.

Processing equipment

Processing equipment can become a host to food particles and build up over time. The accumulation of these food particles can lead to mould growth, which causes unpleasant odours to develop. The bacteria, mould, and yeast on the equipment’s surface will cause the equipment’s surfaces to become unsanitary. The byproducts of these growths (indole, skatole, and geosmin) can lead to putrid, musty, earthy, and fecal aromas.

Bacteria

Bacteria is one of the leading causes of unpleasant odours in a food manufacturing environment. It is much worse than the strong odours emitted by food processing, as it is a distinct decaying smell. Microbes like clostridium, escherichia coli, and pseudomonas damage workers’ health and safety and can emit rotten egg smells.

Consequences of food odours

Now you know what causes food odours in the manufacturing industry, let’s discuss the consequences for staff and operations.

Reducing product integrity

Product integrity is the cornerstone of success for a food manufacturing facility, and it’s important to protect it at all costs. If your facility has a distinct rotten egg, fecal, or burning smell, this will most likely compromise the quality of your products.

Poor job satisfaction

Workers have a right to clean, breathable air. While there are no immediate or long-term health risks associated with pungent odours, your employees might experience a change in taste and smell.

Your employees’ olfactory system is overwhelmed as they breathe in intense burning, fecal, and egg-like smells. The olfactory system will become desensitised to such odours to reduce strain. This can affect the employees’ taste palettes and sense of smell.

Potential health risks

There are health risks associated with strong odours in the manufacturing industry. Firstly, if smells are caused by bacteria and poor sanitation processes, hygiene becomes a concern. Your employees will be breathing in bacteria and waste byproducts that could quickly deteriorate their health and cause them to become ill. Here are some of the ways smells can affect your workers’ health:

- Respiratory irritation

- Nausea and discomfort

- Reduced concentration and productivity

- Psychological distress

- Headaches and fatigue

- Poor quality of life

As an employer, you must ensure your employees are safe, content, and happy. Proper odour management is essential to avoid litigation and poor employee retention rates.

What are the best strategies for managing unpleasant food odours?

Ventilation is the key to managing unpleasant food odours. Here are the top recommended food odour eliminators for the Australian food processing industry.

Roof Fans

If you want to extract heat, steam, and dust from your indoor space, you can do so with a Roof Fan. Here are the various types of roof-mount food processing fans to choose from based on your facility’s specifications:

- Curb Base Hooded Roof Fan – a Curb Base Hooded Roof Fan fits onto the curb of your roof structure to provide vertical discharge for unpleasant odours in a food manufacturing environment.

- Profile Base Hooded Roof Fan – this fan fits onto your roof profile to provide extraction, with guards to prevent rain water and other debris from entering the property.

- Vertical Discharge Roof Fan – this fan type provides vertical air movement, reducing air pockets and providing air circulation while offering extraction for strong odours.

Roof fans are ideal if you have limited floor space and high ceilings, and they can also be the most suitable choice for multi-story buildings as they eliminate odours and heat on higher floor levels.

Exhaust Fans

You can choose from Side Wall, End Wall, and Wall Plate Exhaust Fans. These fans expel odorous air from your facility without allowing debris from outside into your facility. They are lightweight and streamlined solutions perfect for saving space in your facility.

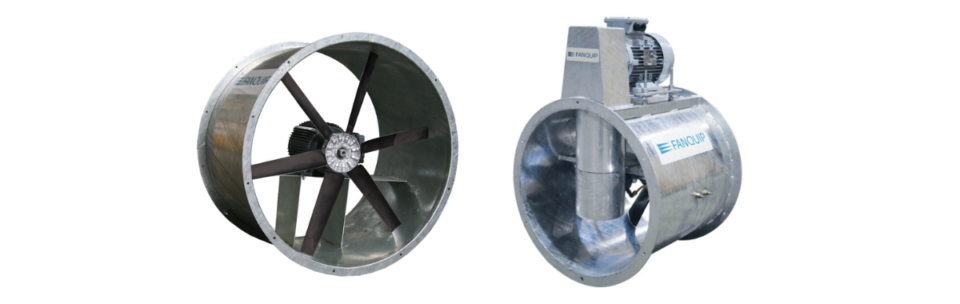

Axial Fans

Axial Fans help remove and dispense contaminated air produced during industrial processes, which generate heat, steam, dust, and other harmful emissions. They create a steady stream of airflow parallel to the fan’s axis to effectively manage odours in a food manufacturing environment.

Choose Fanquip for odour management solutions

Managing odours in your food processing facility helps keep your workers healthy and improves employee retention rates. Ventilation is the cornerstone of odour management.

If you are seeking ventilation solutions to mitigate food odours, improve product integrity and increase employee satisfaction, Fanquip’s ventilation experts are on hand to recommend the top solutions for odour management based on your specifications. Contact us today to access expert ventilation planning.